Combining maths and bubbles to boost gas production

By Dr Mahshid Firouzi University of Queensland with Prof Brian Towler and Benjamin Wu UQ School of Chemical Engineering

How would you like to really see what’s going on in your coal seam gas (CSG) production well? Counter-current, gas and water flow in an annulus is not what we’re used to. New laboratory infrastructure at The University of Queensland’s Centre for Coal Seam Gas (UQ CCSG) has been built to investigate the complex interaction of gas and water flows within CSG wells, which will improve understanding of well production and well infrastructure performance.

CSG (or coal bed methane / CBM) supports Australia’s energy future, both domestically as a cleaner transitional source of energy replacing coal for the coming decades, and for export as LNG.

In order to extract CSG from the coal seams, groundwater needs to be removed to reduce the flowing bottom-hole pressure (FBHP—the pressure at the base of the well), to allow gas to flow into the wellbore. Depending on the gas and water flow rates and flow geometry, different flow behaviour (regimes) such as bubble flow, heterogeneous flow and falling film flow are established, which determine the well deliverability. FBHP is an informative parameter representing flow behaviour in the well. Prediction of the FBHP is key to forecasting well production, tracking well capacity and optimising well production.

A range of mathematical models are available in industry software which enable prediction of the FBHP. However, these models are designed for conventional wells, which are significantly different from CSG wells. Unlike conventional wells, where gas and liquid flow co-currently in a pipe, in CSG wells water and gas are produced into an annulus (the gap between two pipes). Water and gas are separated by allowing the water to flow downwards towards the intake of a pump at the base of the well while gas is allowed to flow upwards to the surface. Therefore, employing the correlations for conventional wells may not be appropriate for CSG wells and may lead to unreliable prediction of flow pressure and well production.

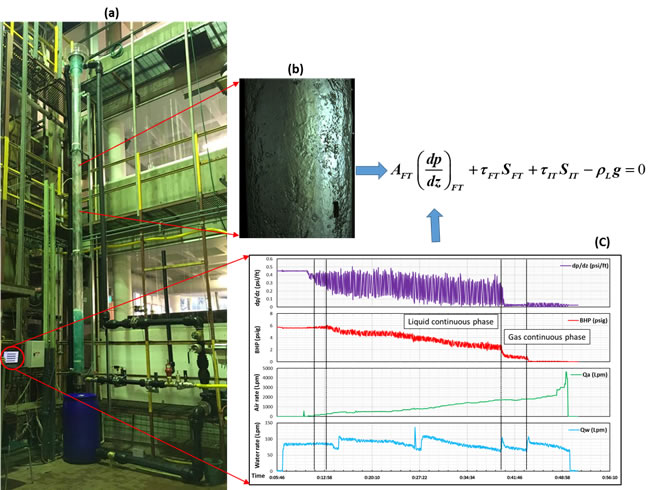

To resolve this issue and better understand the wellbore gas-water flow, researchers at The University of Queensland have designed and constructed a laboratory flow simulator that closely mimics the production zone of a CSG well. Figure 1(a) shows the laboratory setup for simulating counter-current gas-liquid flow behaviour in a CSG well. This wellbore flow simulator, hosted by UQ’s School of Chemical Engineering, is composed of an 8 metre high acrylic annulus with a casing (external pipe) diameter of 170 mm (6.69 in) and tubing (internal pipe) diameter of 70mm (2.76 in), which is the same size as typical CSG wellbores.

The acrylic material allows researchers to observe the flow behaviour at varying gas and water rates; up to 1200 litres per minute of water and 8000 litres per minute of gas. The wellbore flow simulator is equipped with sensors to monitor flowrates, pressure gradient and downhole pressure. The flow behaviour (regime) is recorded using a high speed camera for post analysis.

The recorded flow images, Figure 1(b), enable researchers to identify flow regimes and mathematically describe flow behaviour of gas and water for varying gas and water rates under different operating conditions. The mathematical models developed from physical principles will be tested and validated using the acquired laboratory data shown in Figure 1(c) and field data, prior to implementation.

Figure 1. (a) Laboratory wellbore flow simulator, (b) still of a flow regime recorded by a high-speed camera and (c) signals acquired from flow and pressure sensors across the wellbore flow simulator.

The project findings have provided a clear insight into the flow behaviour in a CSG well which is a key in wellbore control and optimisation. This allows engineers to better understand the signals and data collected at the surface relating to flow interactions occurring 400-900 metres underground.

Additionally, the laboratory wellbore flow simulator has the capability to investigate the performance of downhole pumps used for well dewatering. These pumps are sensitive to the produced gas and solid particulates and very expensive to replace. Experimental investigation of pumps in the wellbore flow simulator can potentially improve the pump runtime and reduce the downtime of gas wells by providing a better understanding of the pump performance under different operating conditions.

More information about The University of Queensland’s research on coal seam gas is available from UQ CCSG www.natural-gas.centre.uq.edu.au

Acknowledgment: The UQ Centre for Coal Seam Gas is funded by the university and the CSG industry (Arrow Energy, APLNG, Santos (2011 – 2021) and Shell/QGC (2011 – 2017). This project received funding through UQ CCSG and the Advance Queensland Research Fellowship program (Queensland Government). OptaSense® (http://www.optasense.com/) has also provided a Distributed Acoustic Sensing system for additional monitoring capability.

Dr Mahshid Firouzi is an Advance Queensland Research Fellow in the School of Chemical Engineering at the University of Queensland. Mahshid holds a BE and ME from Iran University of Science and Technology and a PhD in Chemical Engineering from the University of Queensland. Mahshid’s research interests focus on the experimental study and mathematical modelling of gas-liquid-solid interfaces, thin liquid films, foams and multiphase flows. Mahshid has a strong interest in practical research collaborating with industry across a broad range of areas with the focus on energy.

Contact: Dr Mahshid Firouzi The University of Queensland email: m.firouzi@uq.edu.au or ph. 07 3346 3260.

Read the full article published in the Australian Energy Review magazine: http://australianenergyreview.com.au/combining-maths-and-bubbles-to-boost-gas-production/