Well productivity: Thermal stimulation

This research measured how heating the coal seam affects the diffusion flow and how this may impact well productivity over time.

The research was conducted because improving gas production from individual wells provides an economic advantage for the CSG companies. In addition, improved gas production results in increased royalties which support the provision of government services; and improved well performance may result in the need for fewer wells.

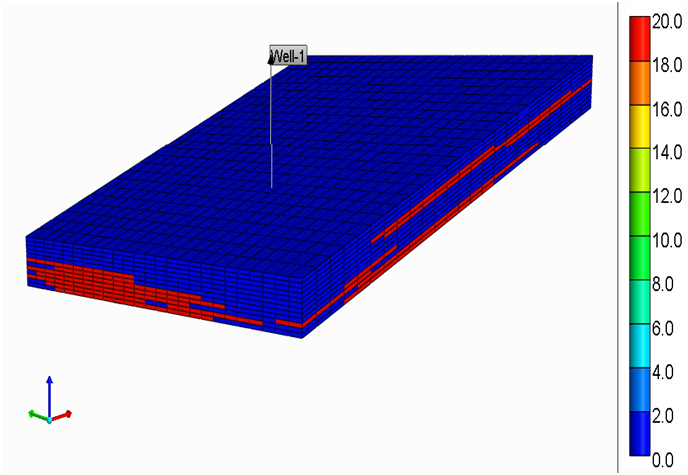

The extraction of coal seam gas is controlled by a number of chemical and physical factors associated with the storage and transport of gas through the sub-surface. The rate at which gas is produced from a well depends on two key factors: the rate of gas release from the coal itself, and the rate of movement through the cracks and cleats in the coal to the gas well. The rate of gas release is highly temperature dependent, so in situations where the main resistance to flow is dominated by gas diffusion from the coal, changing the reservoir temperature offers a possible method for stimulating gas production rates. The cleat permeability is hardly affected by temperature at all, so where this is the dominating resistance, other methods need to be used.

This research measured how heating the coal seam affects the diffusion flow and how this may impact well productivity over time. This investigation also reviewed existing and new methods for heating the subsurface and provided a preliminary assessment of both technical and economic feasibilities of using these methods to improve well productivity.

The research found that increasing temperature did increase well productivity, that is, the volume of gas extracted from the well. However this technique is not economically viable due to the cost of available heating technologies.

PROJECT OUTPUTS

- Description: Interplay of reservoir temperature, and diffusion flow and improvements to well productivity.

- Report: Effect of subsurface temperature on the rate of Darcy flow and diffusion flow.

- Report: Economic feasibility of subsurface heating technologies.

- Research poster: Centre Research Review (2013).

|