Well productivity: Environmental stimulation technologies

This project is aimed at devising new and environmentally sound stimulation technologies capable of increasing the permeability of various coal seam types in order to increase gas production. The study will also examine how permeability changes in response to different chemical treatments and will provide a technical, environmental and economic assessment of each treatment.

Better understanding of low permeability and the methods/techniques that can address the causes of low permeability can improve gas recovery from individual wells and increase the time that the well can operate economically. Both of these factors may decrease the number of wells required to extract the gas from an area of low permeability coal.

BACKGROUND

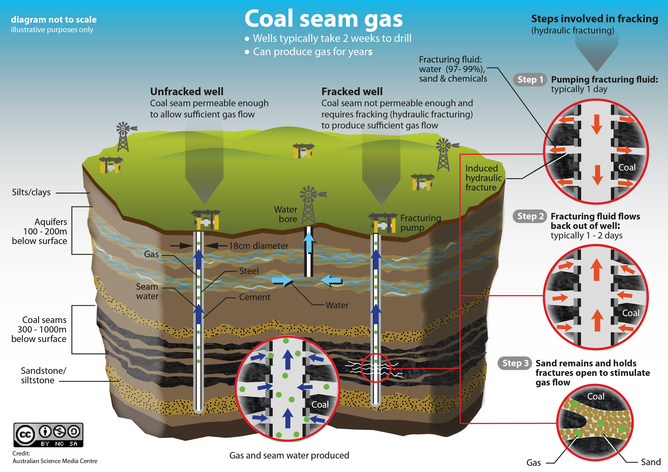

The CSG industry uses hydraulic fracturing processes to increase permeability in the coal seams in order to increase gas production.

Mineral and organic content varies in the coal formations and consequently the composition of the coal can affect the performance of an individual chemical stimulant at different locations.

Coal is found in seams (layers) that have been deposited at different times, under different environmental conditions and subject to different geological processes. Consequently, coal is not a uniform substance, and there is a lot of variability within and between seams which can affect how easily gas and water flow through the coal. In some areas gas and water will flow easily (the coal is highly permeable), while in others the physical structure of the coal restricts gas and water flow (the coal has low permeability).

A range of techniques have previously been developed to deal with low permeability, but their effectiveness varies due to the physical nature of the subsurface.

This project will evaluate the potential of different intervention techniques to overcome low permeability in different geological settings.

INITIAL SCOPING STUDY REVEALS NEED FOR FULL-SCALE RESEARCH

An initial scoping study completed a comprehensive review of existing scientific literature and current academic/industry research programs; laboratory testing of different methods of increasing permeability in coals from a range of representative coal samples; and development of new modelling methods that more accurately represent processes in the region’s coal seams.

Experiments studying the effect of chemicals on swelling were identified as important in developing foundation knowledge and informing future experimental methodologies. Stress-dependent relative permeability experiments are also important. A series of initial permeability experiments were carried out on acid, solvent and oxidant stimulation.

The initial research improved understanding of the complex chemical and physical mechanisms occurring within a coal formation during stimulation and demonstrated the value to industry for development of a large-scale project on environmental stimuation. The large-scale research now underway is supported by ARC Linkage funding

PROJECT OUTPUTS

Scoping

- Research poster: Advanced Environmental Technologies for Coal Permeability Enhancement, Centre Research Review (2016)

- Report: Permeability changes achieved by the application of different chemical treatments and commentary / analysis regarding the chemical and physical mechanisms associated with the permeability changes.

- Report: Performance of tested stimulation chemicals, including technical, environmental and economic assessments.

- Report: Nature of low permeability coals in representative coal sample localities.

- Report: How water blockages can occur in spaces within the coals and the effect that these can have on gas production.

- Report: Options for improving coal seam permeability through chemical and other treatments, focusing on the physical components of the coals and any cleat infill materials in representative coal sample localities.

- Summary of methods: To identify and describe the physical characteristics of low permeability coal where it occurs.

Modelling methods that account for capillary held fluid blockages in the coal pore network. - Potential interventions: Which show promise for increasing coal permeability.

- Publication: Mahoney SA, Rufford TE, Rudolph V, Liu KY, Rodrigues S, Steel KM (2015), Creation of microchannels in Bowen Basin coals using UV laser and reactive ion etching, International Journal of Coal Geology, vol 144-145, pp 48-57.

- Conference paper: Mohoney SA, Rufford TE, Rudolph V, Steel KM (2015), The effect of coal rank on wettability and capillary pressure in a single cleat, International Conference on Coal Science and Technology, Melbourne, 27 September - 1 October, 2015.

Research posters: Two research posters were presented at the Centre Reseach Review (2015)

Phase 1 (scoping) outputs:

- Mahoney, S.A., Rufford, T.E., Rudolph, V., Liu, K.Y., Rodrigues, S., Steel, K.M. (2015) Creation of microchannels in Bowen Basin coals using UV laser and reactive ion etching, International Journal of Coal Geology, 144-145,48-57.

- Mohoney, S.A., Rufford, T.E., Rudolph, V., Steel, K.M. (2015) The effect of coal rank on wettability and capillary pressure in a single cleat, International Conference on Coal Science and Technology, Melbourne, 27 September - 1 October, 2015.

- A summary of methods to identify and describe the physical characteristics of low permeability coal where it occurs.

- A report which describes the nature of low permeability coals in representative coal sample localities.

- A report regarding how water blockages can occur in spaces within the coals and the effect that these can have on gas production.

- Modelling methods that account for capillary held fluid blockages in the coal pore network.

- A report discussing options for improving coal seam permeability through chemical and other treatments, focusing on the physical components of the coals and any cleat infill materials in representative coal sample localities.

- A set of interventions which show promise for increasing coal permeability.

|

Image attribution: Coal seam gas explained, Australian Science Media Centre, CC BY-NC-SA