Silica characterisation in the coal seam water train

The aim of this project is to develop new ways to mitigate silica-associated scaling during Reverse Osmosis (RO) treatment of CSG water. It investigates how the type and level of silica present in coal seam water behaves at different stages of RO process during this treatment.

This study gains a richer understanding of silica/silicate chemistry through the RO stages, to assist in identification of the most appropriate techniques to mitigate silica-associated scaling. It will focus on developing new ways to mitigate scaling by considering silica and silica-rich nanoparticles in concert with hardness cations (calcium and magnesium), with the aim of better managing these cations so to mitigate different types of silica scaling and fouling phenomena.

This ensures effective management of existing assets (lowering operation expenditure) and potentially enables higher water recovery and reduced brine volumes. In addition, lowering chemical consumption would make the treatment process more environmentally-friendly.

Expected outcomes include more productive and effective use of assets (lower operation expenditure), improved RO pre-treatment and the environmental benefits of less chemical waste and higher water recovery, reducing the cost of water processing.

This research project commenced in 2017, following the recommendations of an initial baseline scoping study conducted in 2015.

Background

Due to its relatively high salt concentration, CSG water often has to be treated before disposal or beneficial reuse. Reverse osmosis (RO) membrane separation is widely used for CSG water desalination, with the products being re-useable fresh water and the waste being brine. Management of this brine is one of the key challenges for RO desalination plants. One of the objectives is to maximise water recovery and minimise brine volumes.

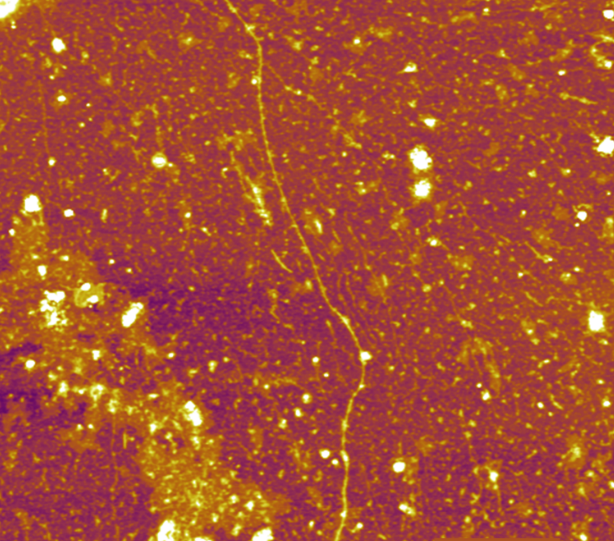

Part of the cost of CSG water treatment is associated with the operation and maintenance of the water treatment facilities. Silica, which is one elements present in coal seam water, can particularly affect the performance of the RO plant. Silica and/or silicate scaling that precipitates in the RO and brine concentration equipment can result in reduced performance and increased maintenance costs for cleaning, down time, and membrane replacement.

Silica concentrations and the forms that it occurs in, fluctuate widely through the RO stages and can be dependent on the local pressure, temperature, pH and water chemistry. As a result, different techniques may be necessary to effectively manage silica at different stages of the treatment process. The scoping research sampled and analysed silica/silica-rich particulates through existing water treatment stages.

Project resources:

- Publication: Silica fouling during groundwater RO treatment: The effect of colloids’ radius of curvature on dissolution and polymerisation (2019)

- Research poster: Aseanian Membrane Society (2018)

- Publication: Silica fouling during CSG produced water treatment by RO membranes (2018)

- Publication: Advanced microscopy of inorganic colloids sampled from consecutive stages of RO filtration (2017)

- Publication: Insight into initial stages of silica scaling employing scanning electron & atomic force microscopy approach (2016)

|

|