Reducing fines damage: selective wellbore coating

This project aims to develop a completely new approach to control solids production in coal seam gas wellbores using a selective phase-inversion polymer coating.

The production of fine solids is a key technical issue affecting CSG wells productivity in Queensland, and leads to 10-15 days production downtime a year.

The expected outcomes of the project include:

- Fundamental understanding of the solids breakage phenomena

- A predictive tool to classify potential solids risks in CSG wells

- A novel rock-selective wellbore coating technology to control solids production.

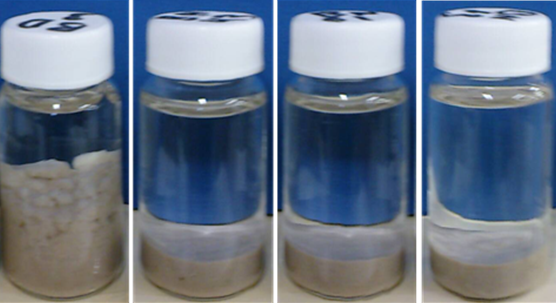

The approach will take advantage of the low permeability of mudrocks to form a protective barrier across clay-rich layers while remaining permeable across the gas-producing coal seams.

The potential economic impacts from the project are lower gas production costs and improved gas supply security.

BACKGROUND

Coal seam gas is extracted from the coal seams by gas wells that are drilled down to the target coal seam. The wells remove both gas and water from the coal seam, however, there are often small amounts of rock and silt that are disturbed by the gas/water flow. These fine particles can be naturally present within the coal seam or created by several different processes associated with extracting the gas, such as drilling activities or rock fracturing.

These particles (known as fines) can collect in the fractures and pore spaces in the coal seam, acting as a barrier to gas flow and reducing gas production from the well. They can also build up in the moving parts of the pump that sits at the bottom of the well, requiring the well to be shut down at intervals for the pump to be serviced.

INITIAL SCOPING STUDY REVEALED NEED FOR FULL-SCALE RESEARCH

The issues of fines sparked an initial scoping study, which investigated:

- How the fine particles are created under different circumstances and developing an understanding of how differences in the quality of the coal can affect the amount of fines that are produced.

- How the fine particles move through the cracks and fractures in the seam and the effect that this has on the flow of gas and water through the rock to the well (the permeability of the rocks).

- What mitigation strategies can be used to decrease fines production or limit the impact of decreased permeability. Mitigation options may include factors associated with well location, well establishment and production strategy.

The initial research demonstrated the value to industry for development of a large-scale project on managing files. The large-scale research now underway is supported by ARC Linkage funding

PROJECT OUTPUTS

Scoping

- Research poster: Centre Research Review (2015)

- Literature review: Technologies for stabilising clay particles

- Report: Experimental program, findings and recommendations for large-scale research

|