Enhancing CSG well production through well bottom-hole pressure control

This project aims to develop novel mathematical models to precisely estimate the flowing bottom hole pressure (FBHP) in CSG wells to replace the available models in industry simulators, which were designed for conventional wells.

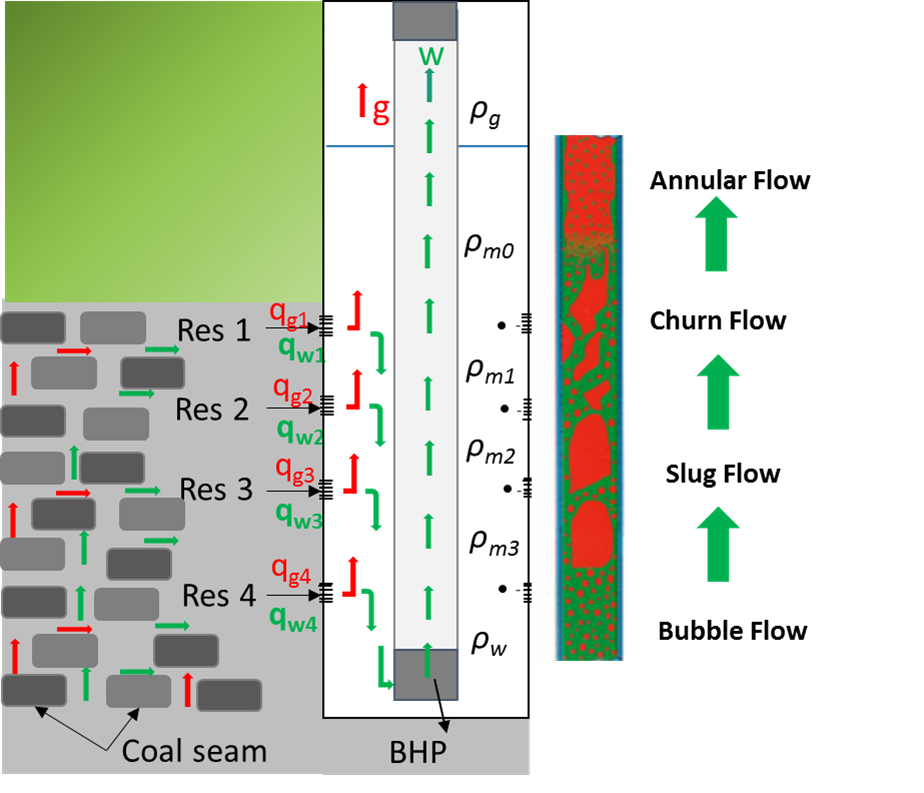

Estimating wellbore pressure profiles in a coal seam gas well (CSG) is important for predicting the production rates of wells.

CSG extraction is associated with production of a significant amount of water, which is removed to reduce the flowing bottom-hole pressure (FBHP) to enhance well production. Reducing the FBHP and therefore abandonment pressure (the point where the production of CSG wells is no longer economic) increases the CSG recovery factor.

More accurate modelling will assist companies to enhance gas production with reduced cost and environmental impact.

The likely outcomes of the project over five years are as follows:

- Mathematical models for predicting the FBHP and free-flow in CSG wells.

- Enhanced gas recovery.

- A commercialised system model.

- Evaluation of the potential use of predictions of free-flow and fluid level to minimise pump damage and therefore decrease well maintenance costs.

Dr Firouzi has been awarded an Advance Queensland Research Industry Fellowship to complete this research.

RESEARCH NEED IDENTIFIED IN INITIAL UQ SCOPING RESEARCH PROJECT

This project follows on from an initial project in this space which investigated the flow behaviour, flow pattern as well as flooding and pressure profile of counter-current two-phase flows in annuli both mathematically and experimentally.

Estimated pressure profiles are crucial in designing artificial lift systems, that is, using artificial means to dewater CSG wells and reduce the bottom hole pressure (BHP). The available models in industry simulators were originally designed for conventional wells, where gas and liquid flow concurrently in a pipe. However, the upward flow of gas and downward flow of water in the annulus of a CSG well establishes a counter-current two-phase flow. These models are inadequate for evaluating reservoir/well performance especially where pressure gradients are large.

The initial project:

- Developed models for counter-current two phase flows based on the available mechanistic models for co-current two-phase flows to predict the pressure profile.

- Conducted an experimental study to identify flow patterns and measure pressure gradients to validate the modelling predictions for pressure loss, flow transition and flooding in counter-current two-phase flows in annuli.

This initial research supported the need for development of a full scope of research in estimating the flowing bottom hole pressure (FBHP) in CSG wells to replace the available models in industry simulators, which were designed for conventional wells. Dr Firouzi has been awarded an Advance Queensland Research Industry Fellowship to complete this research.

PROJECT OUTPUTS

Current

- Article: Combining maths and bubbles to boost gas production (2018)

- Research poster: Centre Research Review (2018)

- Article: Researcher receives the Advance Queensland Fellowship (2017)

- Publication: A critical review of flow maps for gas-liquid flows in vertical pipes and annuli (2017)

- Research poster: Centre Research Review (2017)

- Research poster: Centre Research Review (2016)

- Publication: Firouzi M, Towler B, Rufford T (2016), Developing new mechanistic models for predicting pressure gradient in coal bed methane wells, Journal of Natural Gas Science & Engineering, vol 33, pp 961-972.

- Publication: Firouzi M, Towler B, Rufford T (2015), Mechanistic modelling of counter-current slug flows in vertical annuli, SPE Asia Pacific Unconventional Resources Conference and Exhibition, Brisbane, 9-11 November 2015. SPE-176885.

Initial scoping deliverables

- Publication: Firouzi M, Towler B, Rufford T (2016), Developing new mechanistic models for predicting pressure gradient in coal bed methane wells, Journal of Natural Gas Science & Engineering, vol 33, pp 961-972.

- Conference paper: Firouzi M, Towler B, Rufford T (2015), Mechanistic modelling of counter-current slug flows in vertical annuli, SPE Asia Pacific Unconventional Resources Conference and Exhibition, Brisbane, 9-11 November 2015, SPE-176885.

|